Custom Mold Tooling

ThermoFab is a one-stop solution for all your plastic enclosure manufacturing needs.

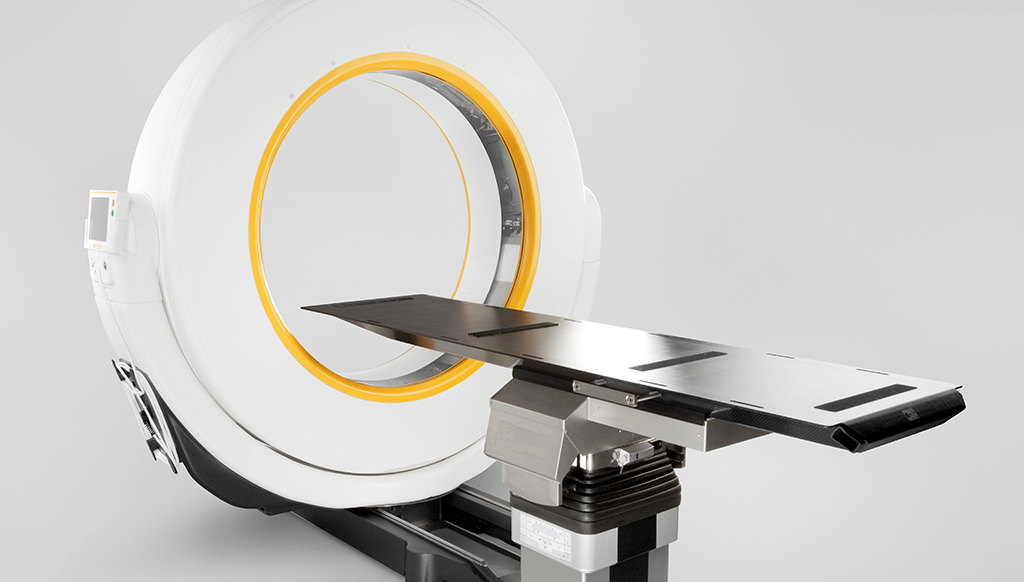

THERMOFORMING

With our thermoforming capabilities, we are equipped to handle projects of any complexity, delivering consistent and flawless results. One of the key advantages of thermoforming is the quick tooling setup, a valuable asset for prototyping and product development which facilitates seamless design adjustments.

Thermoforming allows you to create complex shapes, textures, and undercuts, elevating both the aesthetics and functionality of your product. In addition, its production scalability caters to both low and high production volumes depending on your needs.

ThermoFab’s commitment to expertise, precision, and customer satisfaction sets us apart in the world of thermoforming. We look forward to working with you to bring your projects to life.

Injection Molding

Injection molding is a highly versatile and efficient manufacturing process with a broad range of applications. Its capacity to produce intricate, high-precision parts with tight tolerances is especially valuable in large-scale manufacturing, where cost-effectiveness and efficiency are key.

In parallel, the high mix, low volume (HMLV) molding approach has emerged as a strategic production strategy. HMLV allows you to craft a diverse range of products in smaller quantities, offering the flexibility to meet your specific needs. Within the HMLV framework, design changes are easily implemented, resulting in improved product customization, heightened customer satisfaction, and a competitive edge.

When these two approaches converge, you get the flexibility of HMLV with the precision and custom design capabilities of injection molding. This provides a strategic advantage, combining flexibility and precision in the ever-evolving world of manufacturing.

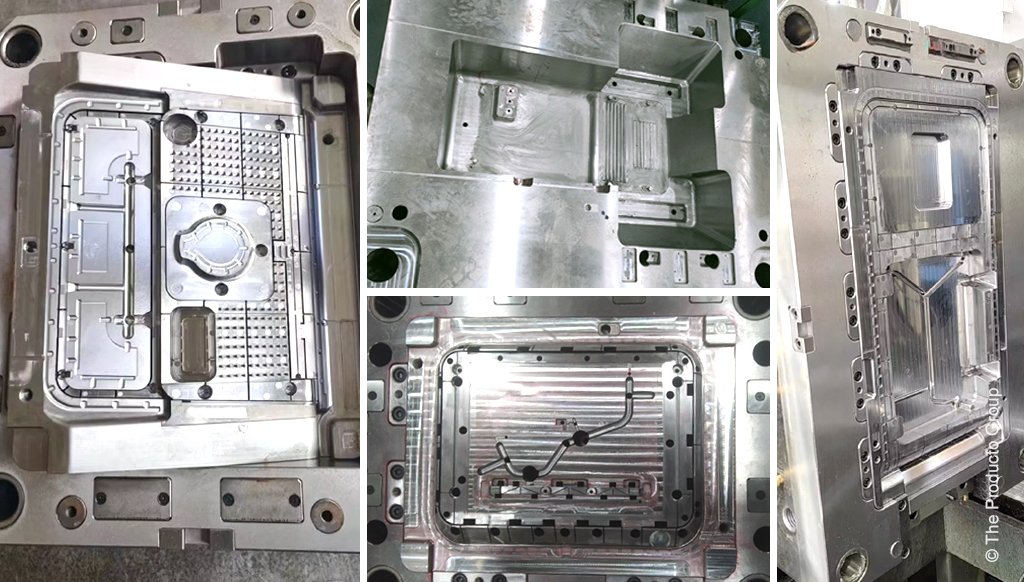

mold tooling

At ThermoFab, we strike the perfect balance between precision and efficiency when it comes to our mold tooling. Mold tooling is fully customizable, which provides the flexibility to produce parts that match the exact specifications of your project. Our engineering team will review your part details and make any revisions for tooling optimization, while ensuring every detail aligns with your vision.

What sets our tooling apart? Our commitment to efficiency, with a lead time of 4-6 weeks, we ensure speed without compromising quality. We use P-20 steel for our injection mold tooling. Its durability and resilience to high temperatures and pressures is unmatched.

In addition, we can produce rapid prototypes for each production part design of your project.

materials of construction

If you need assistance, we can help with material selection from our list of typical engineering plastics below. If you would like to request custom or additional materials, we are more than willing to investigate those options with you.

- Starex Flame-retardant ABS

- Kydex Acrylic/PVC

- Sabic Polycarbonate ABS blends

- Polycarbonate

- ABS

- PVC

- Acrylics

- High impact polystyrene (HIPS)

- Polypropylene

- HDPE

size capabilities

- Can manufacture components up to to 70″ x 47″ x 40″

(1,800 mm x 1,200 mm x 1,000 mm) - Part wall thickness from .04” to .38” (1 mm to 4 mm)