Medical Device Enclosures

ThermoFab provides expert thermoforming or injection molding processes for a multitude of medical device applications.

Medical Device & Life Sciences

ThermoFab is a leading expert in the field of thermoforming and injection molding heavy-gauge custom plastic enclosures for the medical device & life sciences market. We cater to a diverse range of applications, including but not limited to medical devices, genetic sequencing devices, handheld devices, and biotech equipment.

Working with ThermoFab, you have a partner dedicated to providing the highest-quality enclosures tailored to your needs, backed by a wealth of experience and a commitment to excellence.

THE THERMOFAB ADVANTAGE

With a proven track record of excellence in the industry, ThermoFab offers a range of benefits that set us apart as your ideal partner for medical device enclosures.

Vertically integrated turnkey solutions for thermoforming, injection molding, fabrication, enclosure assembly, distribution and inventory management.

High mix, low volume production, ensuring flexibility and customization.

High-quality finishing for a polished and professional appearance.

Rapid prototyping services for quick design iterations, reducing time-to-market.

Competitive pricing, guaranteeing outstanding value without compromising quality.

Use of industry-compliant materials to meet stringent medical standards.

Various coating and material options including copper shielding EMI/RFI coating and antimicrobial material for improved performance and reliability.

Capability to produce multiple-part enclosures of various sizes to accommodate your specifications.

ThermoFab has extensive expertise in thermoforming or injection molding a diverse variety of medical device applications including:

- Camera housings

- Handheld medical devices

- Hospital room panels

- Hospital bed shrouds

- Imagining components

- Interface panels

- Internal medical components

- Laboratory equipment

- Medical cart & support equipment

- Medical diagnostics and testing enclosures

- Medical equipment housings & structural coverings

- Medical laser equipment

- Medical rehabilitation devices

- MET diagnostic equipment

- Microplates

- Monitor / tablet enclosures

- MRI scanner components

- Organ transplant preservation devices

- Sidewalls, shrouds, covers, bases, bezels & enclosures

- Surgical robot enclosures

- Surgical lighting enclosures

- X-ray machines

SURGICAL LASER EQUIPMENT

Refractive cataract surgical laser equipment features side panel with internal formed boss and ribs. Side detail shows .650” undercut created with tooling side action. Close-up shows additional rib support beneath the undercut. Enclosure also shows two-tone metallic side panel with a four-color logo gradation.

DENTAL LASER ENCLOSURE

Dental laser features undercut with sleek and stylish two-tone paint. Part back with plastic enclosure for water bottle. Sturdy front cover with a smooth and streamlined design.

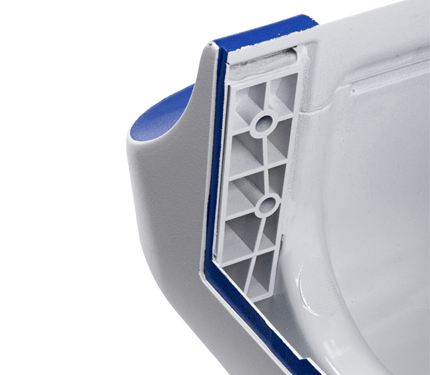

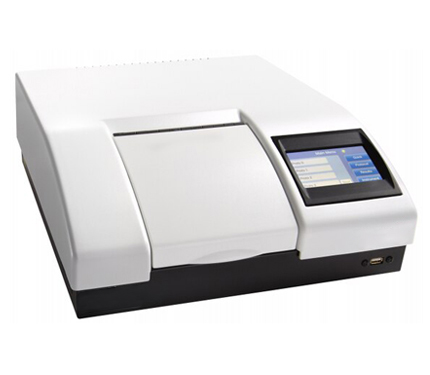

MEDICAL MONITORING ENCLOSURE

Enclosure designed for ventilation monitoring for non-intubated patients. Back of enclosure shows multiple tool inserts and side action. Front view features sleek and modern styling.

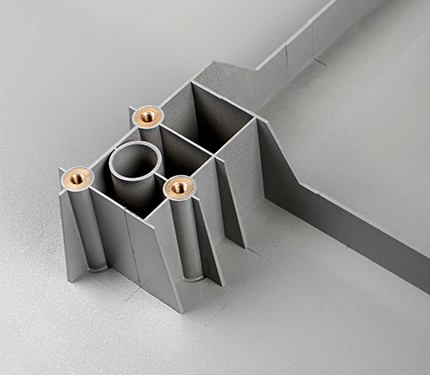

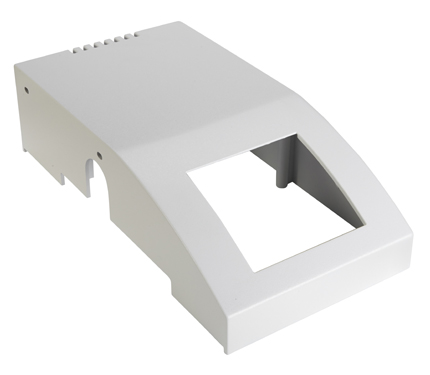

MEDICAL cell imaging ENCLOSURE

Cell imaging cover and door. Underside of enclosure with formed posts and ribs. Clinical procedure enclosure with smooth and streamlined design.