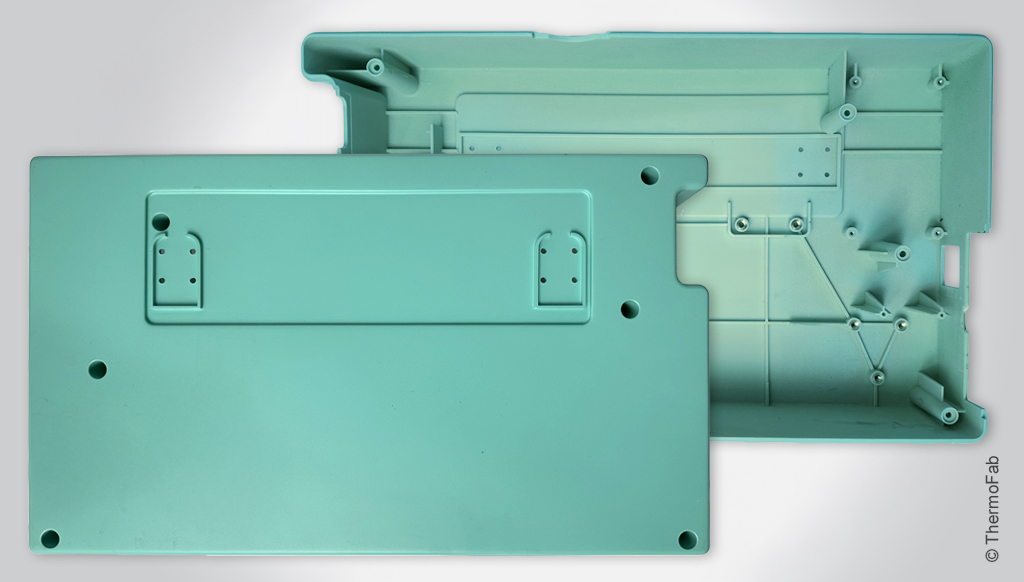

Cast Urethane

At ThermoFab, we specialize in providing cast urethane molding solutions for plastic enclosures and single use components.

HIGH-PRECISION CAST URETHANE SOLUTIONS

Cast Urethane molding is suitable for high-quality prototypes and low-to-medium volume production. This versatile process is ideal for applications requiring detailed features, complex geometries, and a quick turnaround—with rapid prototype lead times of less than 4 weeks. When you need the look, feel, and performance of injection molded parts without the high costs or lead times associated with traditional tooling, cast urethane offers a cost-effective solution.

Known for its flexibility and speed, cast urethane is a top choice for industries such as medical, industrial, robotics, and defense. Our team can replicate complex geometries, overmold features, and color-match parts to exact specifications. Whether you’re validating a design or launching a limited run, ThermoFab’s cast urethane capabilities ensure fast, cost-effective results—without compromising on quality.

Check out our case studies for more information

ADVANTAGES OF CAST URETHANE

Cast Urethane is known for its speed and flexibility, making it a preferred choice for high-quality prototypes and low-to-medium volume production.

- Cost-Effective Tooling: Utilizes silicone or composite molds, significantly reducing initial tooling expenses

- Rapid Turnaround: Accelerated production timelines, making it suitable for prototyping and low-to-medium volume production

- Consistency & Repeatability: Accurately replicates intricate details and complex geometries

- Material Versatility: Urethane materials can be formulated to achieve a wide range of properties, from soft and flexible to rigid and impact-resistant, and can be customized for specific applications

- Customization: parts can be easily customized to incorporate branding elements using painting, silk screening or pad printing to meet specific aesthetic requirements

size capabilities

With our cutting-edge cast urethane capabilities, we’re equipped to produce components of various sizes—including highly intricate designs and low-volume production runs—with precision and efficiency. One key advantage of cast urethane is the design flexibility it offers, including the ability to produce parts without uniform wall thickness constraints.

- Can manufacture components up to 2m (81″) x 1m (39″) x 0.66m (26″)

materials of construction

At ThermoFab, our expert team is ready to match the ideal material options from our network of trusted resin suppliers. We offer an extensive selection of both rigid (ABS like) and flexible urethane materials (elastomeric like), engineered to withstand a wide range of wear and tear. With precise control over durometer and mechanical properties, we can suggest materials to meet your specific performance requirements—ensuring your parts deliver durability, reliability, and optimal functionality.

If you would like to request custom or additional materials, we are happy to discuss those options with you.