ThermoFab, a division of The Producto Group, is a trusted industry leader with over four decades of expertise in thermoforming and injection molding for heavy-gauge plastic enclosures. We are your comprehensive solution for enclosure development and manufacturing, specializing in the medical device, biotech, automation, and test & measurement markets.

From initial design to tooling and production, our expertise ensures your products are manufactured with high-quality materials and tailored to your exact specifications. Discover the ThermoFab advantage and let us bring your vision to life.

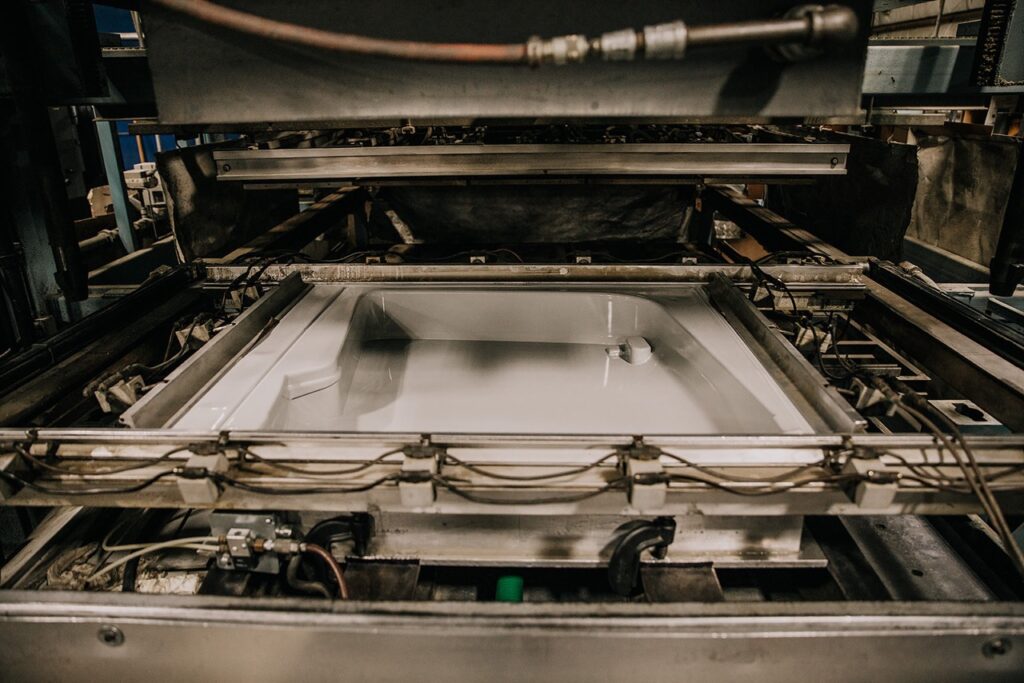

Leveraging state-of-the-art technology, our thermoforming capabilities deliver precision and reliability, producing high-quality components.

Our injection molding capabilities allow us to handle projects of any complexity, producing a wide range of plastic parts and components.

We provide expert application of the thermoform, injection mold, and fabrication processes.

- Design & prototyping

- Tooling manufacturing

- Custom surface finishing and decals

- UL94V-0 materials

Industry Applications

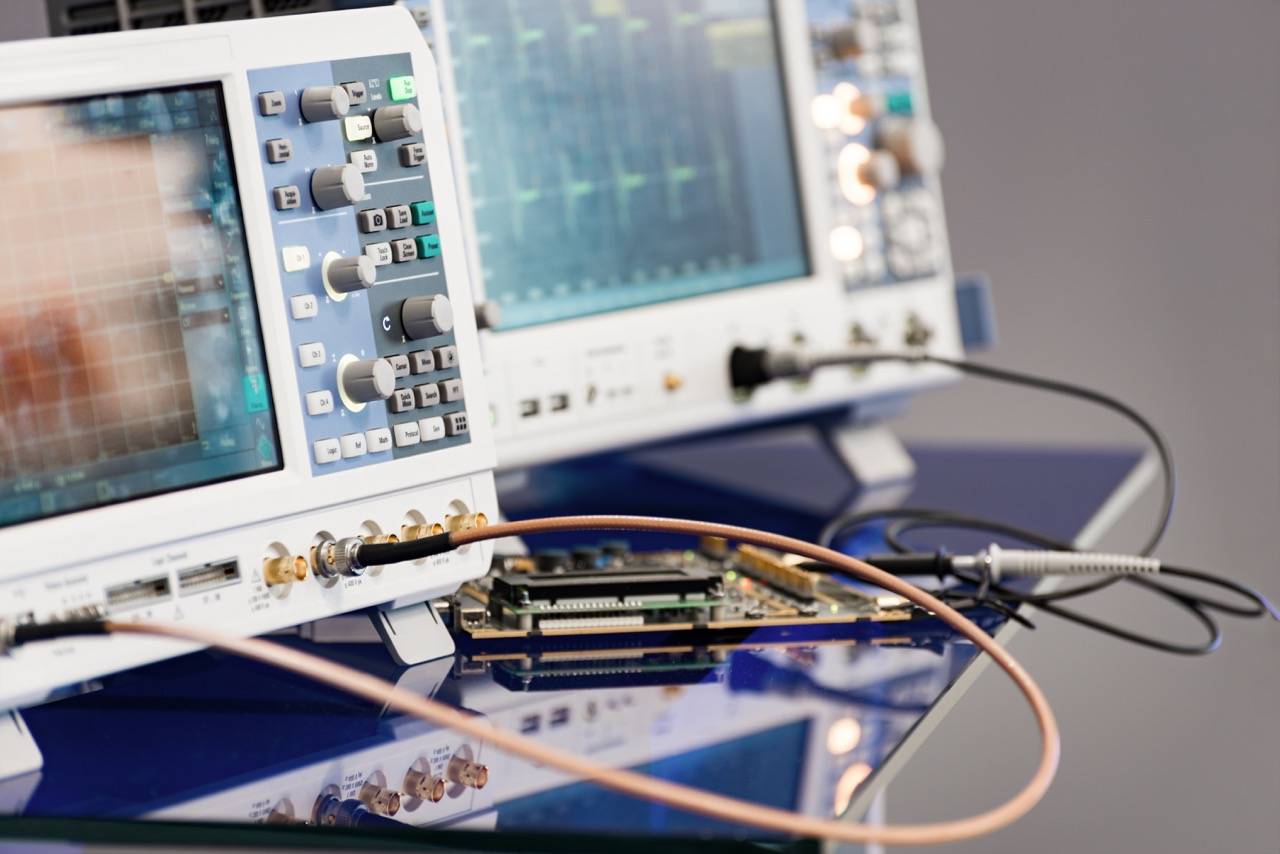

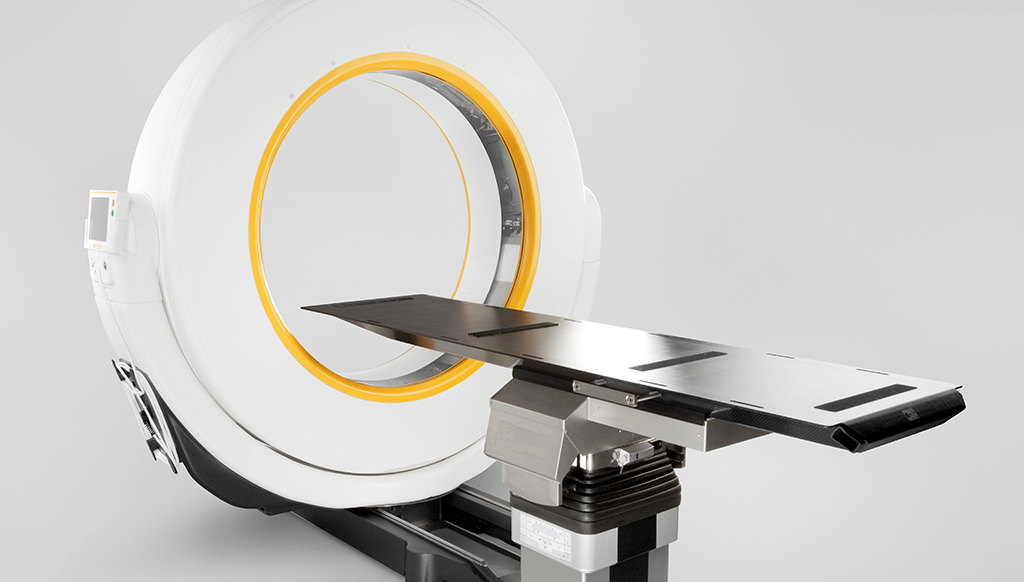

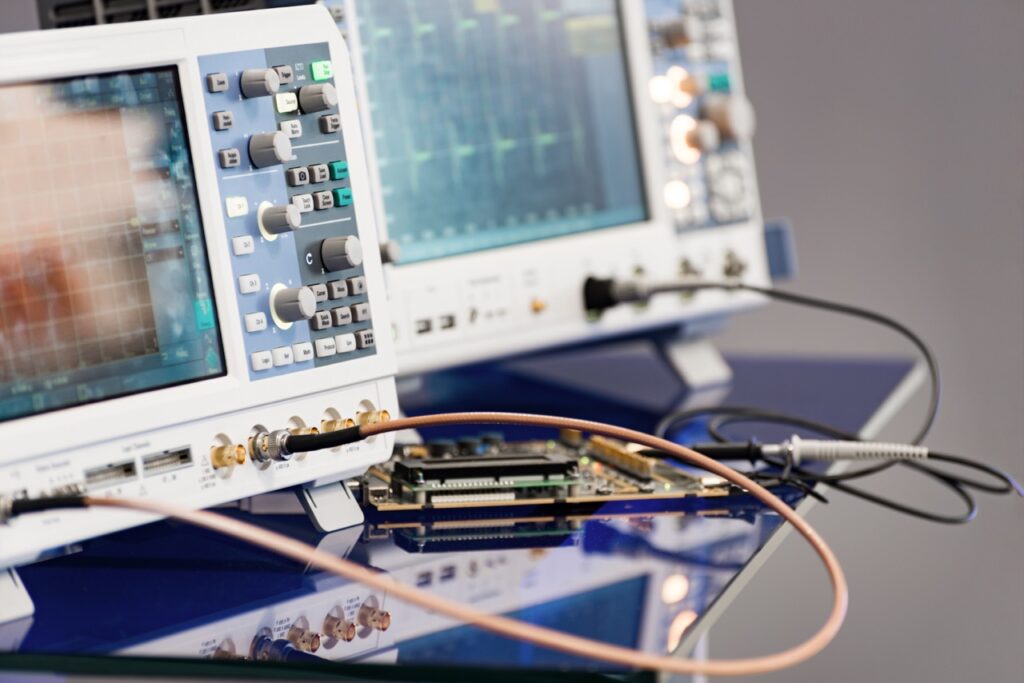

With our extensive experience in a diverse range of markets, we are your go-to partner for enclosure development and manufacturing. Catering to the unique applications needs of the medical & genetic sequencing, biotech, automation, and test & measurement industries.